About Us

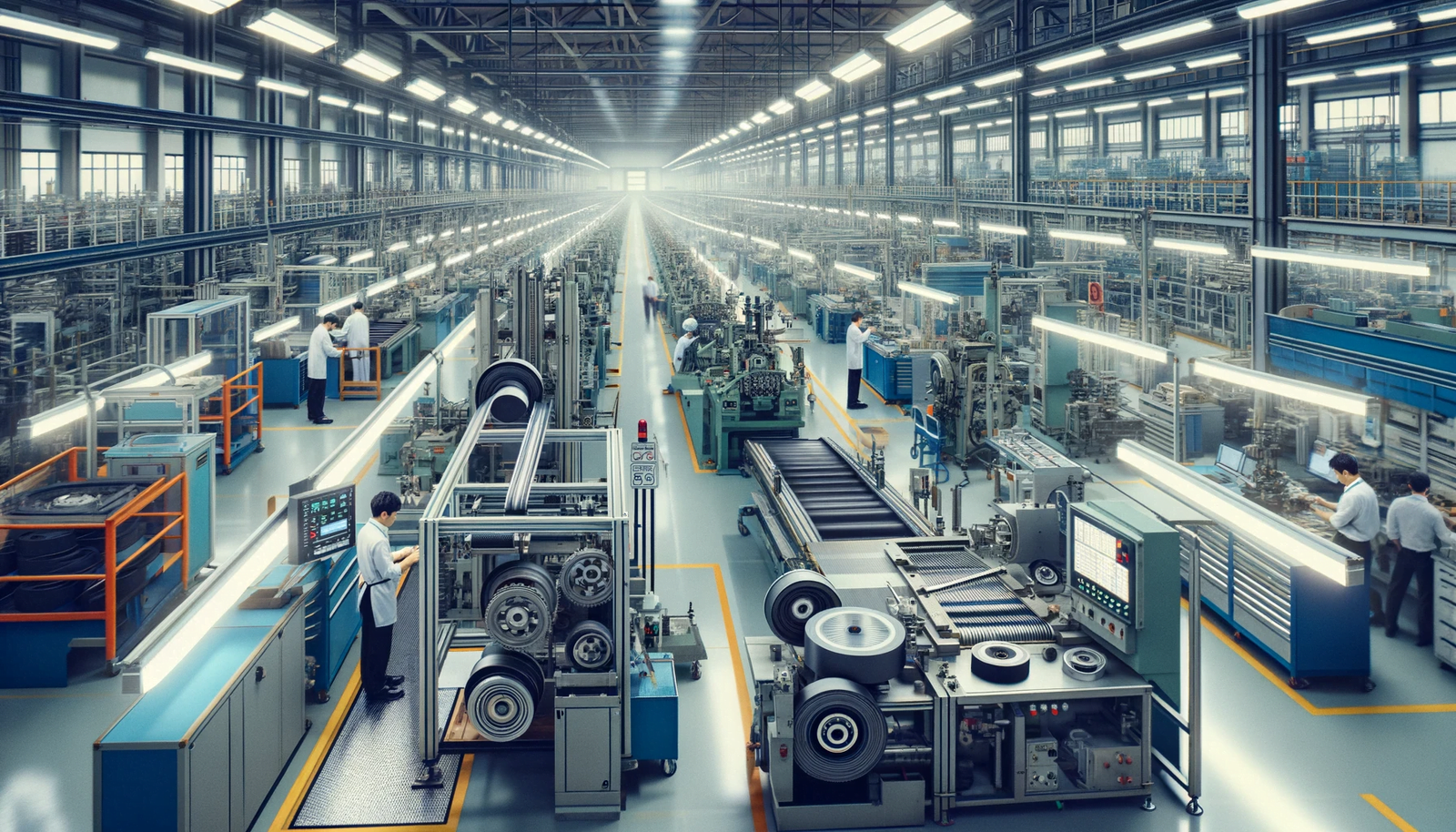

At present, the company has more than 130 rubber belt material formulations, can produce tens of thousands of belt varieties,

Suitable for the world’s mainstream passenger auto models, commercial vehicle models, widely used in agriculture, machinery and equipment, more than 80% of the products are exported to Europe,the United States, Australia, the Middle East, Southeast Asia and other more than 100 countries and regions, is many internationally renowned auto parts sellers, and rubber belt sellers long-term partners.

Our story

In 1999, the factory was established to produce PK belts

2002 through the “ISO 9002”, QS9000, quality system certification

Production started in 2003

2006 Passed the “ISO14001 EMS Environmental Management System Certification”, “OSHMS Occupational Health and Safety Management System Certification”

In 2007 through the “ISO9001” quality system certification

In 2009 Enterprise Technology Center was recognized as “National Enterprise Technology Center”

In 2010 began to produce Cogged belt,Wrapped belt

In 2014, multiple V-ribbed belt surfaces were introduced

In 2018, the pilot certificate of aviation products was approved

In 2002 The Vietnam branch is planned to be established

Strict Quality Control

Raw Material Selection

The first step in quality control is the selection of high-quality raw materials. Factories rigorously select natural or synthetic rubber, ensuring it meets all necessary performance standards. Additionally, suppliers are strictly evaluated to choose only those who can consistently provide quality materials.

Production Process Monitoring

During production, each step is accompanied by meticulous quality checks. Advanced automation systems are used to ensure that the thickness, width, and elasticity of each rubber belt meet the design standards. Real-time monitoring of production lines allows for the immediate identification and resolution of any potential quality issues.

Final Product Testing

Each batch of finished products undergoes rigorous testing, including tests for abrasion resistance, tensile strength, and long-term durability. These tests ensure that each rubber belt performs excellently in practical applications. Products that do not meet the standards are strictly dealt with, ensuring that only qualified products enter the market.

Conclusion

Through these strict quality control measures, rubber belt factories ensure the high quality of their products. This not only wins the trust of customers but also sets a benchmark for the entire industry. Continuous quality improvement and technological innovation are key to maintaining a leading position in this industry.

In summary, strict quality control is not just the cornerstone of the operation of rubber belt factories, but also a guarantee of their long-term success. By continually pursuing excellence, these factories contribute valuable stability and reliability to the entire field of industrial production.

certificate

Longyi Rubber Products factory always adheres to the quality policy of customer first, integrity and dedication, continuous improvement and pursuit of excellence, and has passed IATF 16949 quality management system certification, ISO9001 quality management system certification,

ISO14001 environmental management system certification and ISO45001 Occupational health and safety management system certification.

The products sold by the company meet a series of strict quality inspection standards.